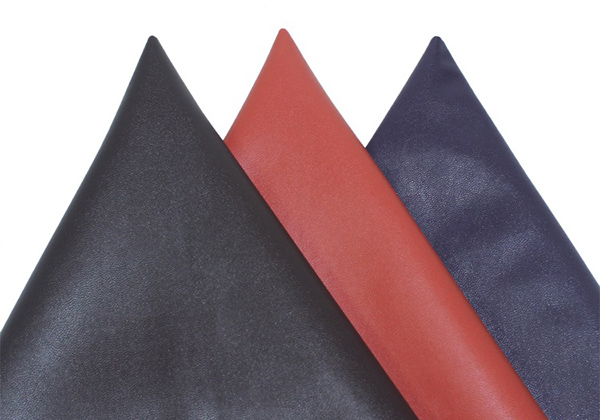

FASHIONABLE MATERIAL . HIGH QUALITY

Wear Resistance

More than five times natural rubber wear - resistant, wear - resistant products are one of the preferred materials

Tensile Property

The tensile strength is up to 70MPa and the breaking elongation is up to 800%.

Tear Performance

TPU film has high tear resistance, tear strength than commonly used rubber

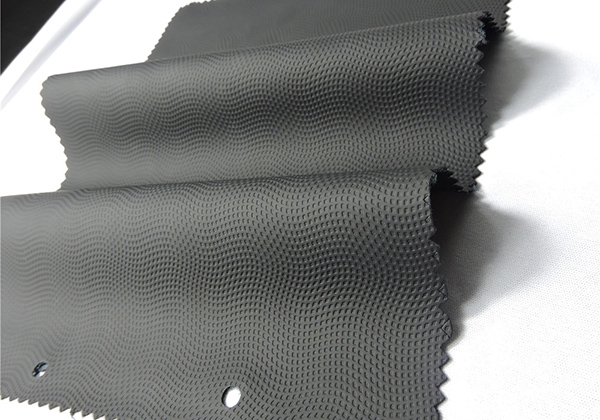

Zigzag Performance

TPU products in different environments can maintain excellent bending resistance, one of the best polymer materials

Hydrolysis Resistance

TPU has good water resistance under turbidity, and no obvious hydrolysis will occur in 1-2 years

Polyester series will be completely hydrolyzed after soaking for half a year or 70 c for 3 weeks or 100 c for 3 to 4 days in water at 50 c, which is one of the reasons why TPU film is suitable for environmental protection

High Temperature Resistance And Oxidation Resistance

TPU has good oxidation resistance. Generally, the temperature resistance of polyester series is up to 130 degrees Celsius and polyether series is up to 90 degrees Celsius

Oil And Drug Resistance

TPU is a kind of strong polar polymer material with little affinity with non-polar mineral oil. It is almost free from erosion in fuel oil and mechanical oil. Among them, the products of polyester series in TPU are of better oil resistance

Low Temperature Performance

TPU film has very good low temperature resistance, usually up to 40 degrees Celsius, is a good alternative to PVC

Air Tightness

TPU is very easy to be fused by high frequency or hot pressure, so it is widely used in aeration products. Generally speaking, air tightness of polyester series is better than polyether series.

Biomedical Performance

TPU film has excellent biocompatibility, non-toxic, non-allergic reaction, no local irritation, no heat source, and is widely used in medical, health and other related products as well as sports and protective equipment

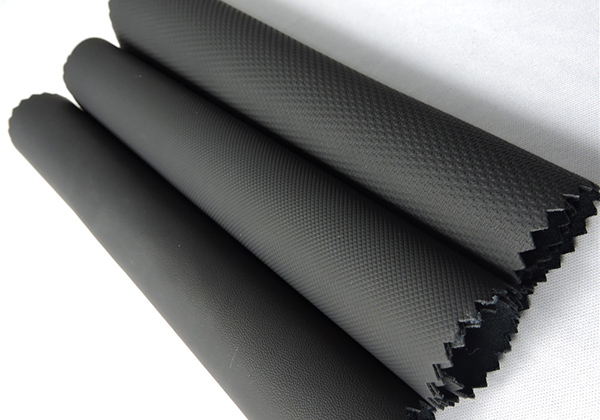

In Combination With The Above Information, To The Summary Of The Advantages Of TPUTPU (Thermoplastic polyurethanes), thermal plasticity TPU elastomer, by including NCO functionality, MDI and OH functionality, POLYOL, 1.4 BG, made by mixing and extruding, with good elasticity, good physical properties, and a variety of mechanical strength is very good, therefore, widely used in injection, extruding, rolling and dissolved into solution such as resin processing way, is the plastic processing industry often use plastic material, made its products cover the range of industrial applications and civil necessities. In recent years, due to the continuous development of new products, the use of thermoplastic PU elastomer is continuously increasing, creating a new opportunity for plastics processing industry with low cost and high added value. TPU (thermoplastic polyurethane) is gaining popularity due to its superior performance and environmental protection concept. At present, TPU can replace PVC

wherever it is used. But the advantages of TPU are beyond the reach of PVC.TPU not only has excellent characteristics of high tension, high tension, strength and aging resistance, but also is a mature environmental protection material. At present, TPU has been widely used in: shoes, garments, inflatable toys, aquatic and underwater sports equipment, medical equipment, fitness equipment, automobile seat materials, umbrellas, suitcases, leather bags, etc. At present, it is widely used in sports shoes: trademark decoration, air bag, air cushion, oil bag, etc. Now, TPU film is applied on sneaker in two trends: one is the popular wind that blows by female sandal, that is, it is high transparent TPU film or cut directly, or screen printing color, or laminated cloth base into net cloth, high cycle forming and bonding on the upper, functional and decorative effect. Second, the waterproof and moisture permeable TPU film is used in combination with the cloth used for shoes to achieve the waterproof and moisture permeable effect.

Its main advantages are

It can make full use of the current production process and production conditions of domestic synthetic leather manufacturers. While producing the more environmental-friendly and environment-friendly TPU resin which can completely replace the traditional PU resin, it will not waste the existing production resources.

She USES alternative solvents such as TOL and DMF that have poor environmental performance without changing the characteristics and functions of products, and is more effective in high permeability, wear resistance hydrolysis and other properties.

Focus is capable of producing products of various specifications and different modulus to meet customer needs for different USES.

It can produce TPU modified resin required by different industries to meet the requirements of different levels.

At present, TPU is being used more and more on synthetic leather, because European and American countries have already listed the PU synthetic leather products containing DMF as the object of elimination. During the 12th five-year plan period, China has also begun to strongly encourage the development and production of water-based ecological products and environmental protection leather products such as TPU.

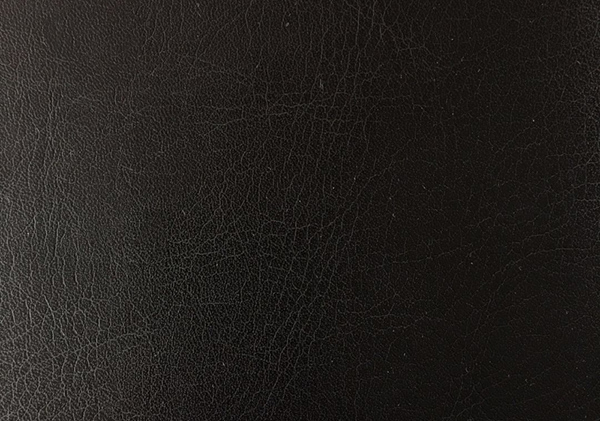

Anti Slip PVC Leathe

Anti Slip PVC Leathe SGS Eco Friendly Mic

SGS Eco Friendly Mic Special-Materials-Ne

Special-Materials-Ne Synthetic-PU-Leather

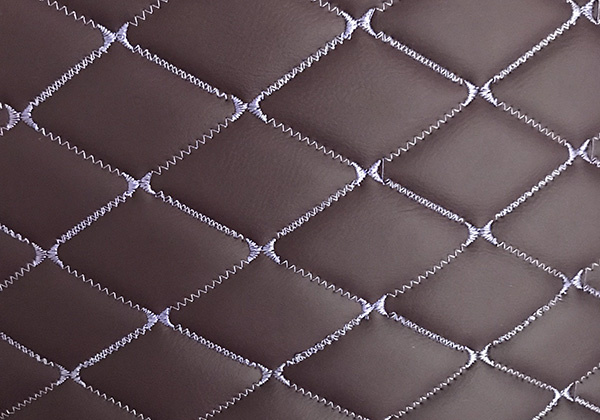

Synthetic-PU-Leather 7D Hand Craft Diamon

7D Hand Craft Diamon 0.45mm Best Price Sy

0.45mm Best Price Sy synthetic pu pvc vin

synthetic pu pvc vin PVC-Vinyl-Synthetic-

PVC-Vinyl-Synthetic- Flexible semi microf

Flexible semi microf Faux Paint To Paint

Faux Paint To Paint  Eco-friendly PVC Syn

Eco-friendly PVC Syn Bonded-embossed-leat

Bonded-embossed-leat Classic Leather Grai

Classic Leather Grai Animal Skin Emboss P

Animal Skin Emboss P ohms per square elec

ohms per square elec black conductive-pu-

black conductive-pu- black-color-screen-t

black-color-screen-t Synthetic-leather-fo

Synthetic-leather-fo Pattern-Faux-Synthet

Pattern-Faux-Synthet embossed-garment-pu-

embossed-garment-pu-