Flocking leather

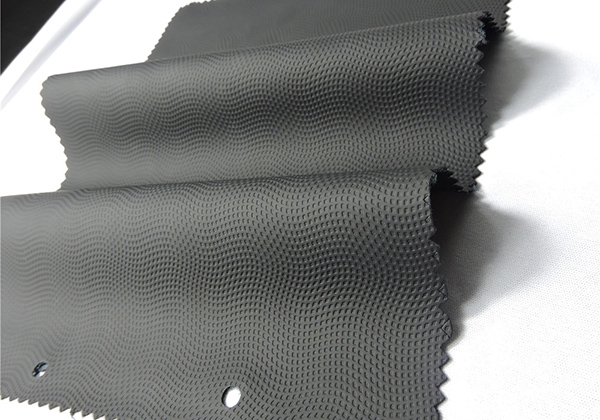

I. Backing Flocking leather

Flocking leather various trade name is not the same, some called recycled leather, long hair flocking, short hair flocking, flocking cowhide powder.

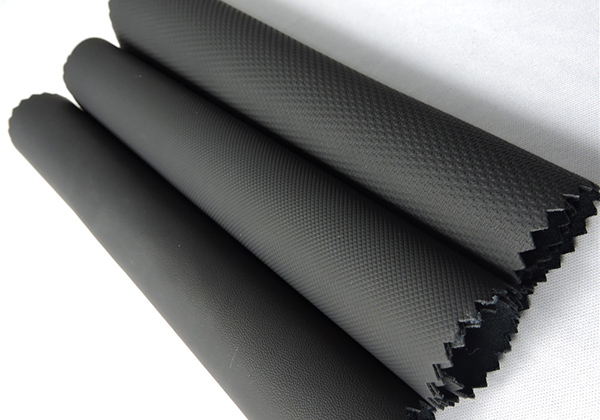

Leather powder with bottom cloth and simulated leather effect, high cost performance, suitable for sofa, luggage, shoes, handbags, notebooks, etc.

Technology is in PU/PVC leather backing cloth will be leather powder or leather, blending chemical raw materials processing and production. PU sole such as non-woven , cotton and silk sole can be flocking, playing the role of leather simulation, flocking has long hair and short hair, according to the requirements of different industries.

There is also a kind of imitation cow anti - flocking leather. It is used for shoes, such as snow jogging boots and leather boots, and also for clothes production.

More than 100 kinds of color products are widely used. It can be used for flocking inflatable bed, inflatable toys, high frequency embossing, Christmas bow, hand garland, gift packaging, handbags, shoes, stationery, furniture and so on.

II.Surface Flocking Leather

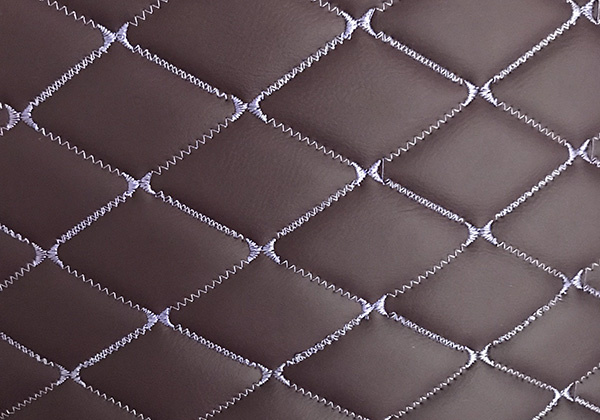

The production method of flocking on grooved groove bottom includes the following steps:

first, take the grooved synthetic leather products, apply flocking pulp on the surface through sizing machine, scrape the flocking pulp on the top of the grooved synthetic leather products with scraper machine, and then apply the required color flocking powder.

Secondly, the villi are made upright through the electrostatic device.

Thirdly, the top of the grain of fluffy powder scraping off, drying finished products.

Because the invention in the synthetic leather flocking, through two scraper process to produce synthetic leather, without losing the synthetic leather surface all kinds of beautiful patterns and colors and in the groove at the bottom of the animal synthetic leather fuzzy feeling, make the product more gorgeous.

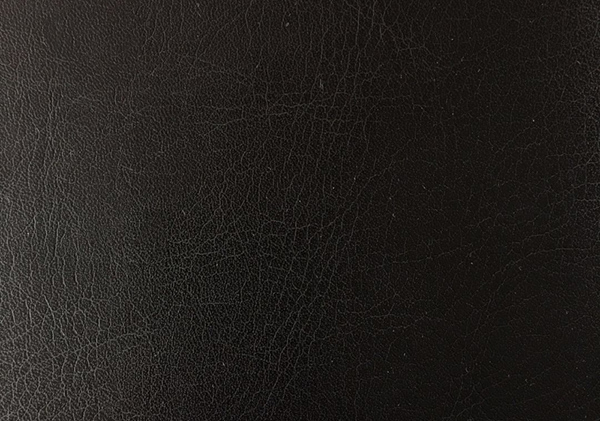

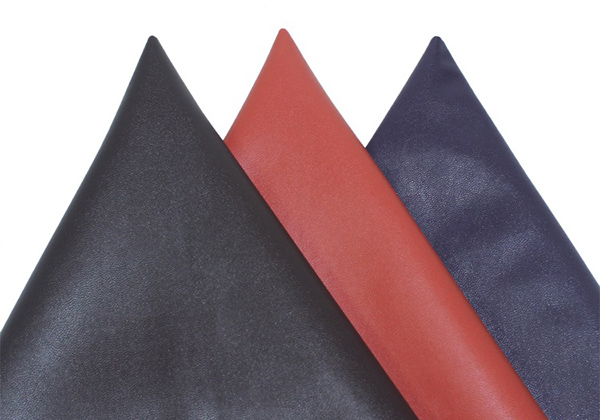

What is surface flocking colored leather?

Flocking color leather features, the advent of flocking color leather, not only to the leather fabric varieties and color is a great complement and development, but also to overcome the original leather dyeing is not thick not colorful, color problems and not very timely with the market changes in color and other shortcomings.

Colored suede leather is made on the basis of the original finished leather "planting" (after electrostatic treatment) a layer of nylon (that is, a fiber cut into pieces), the length of nylon wool is 0.1-3mm.With a special glue, through cross-linking chemical reaction, a strong network structure is formed between nylon wool and leather, and from the "permanent" "planting" of nylon wool on the leather surface, the density of nap leather is made of more than 20 hairs per square millimeter.

The main products are clothing, gloves, shoes and hats, cars, car cushion and other daily necessities.

Flocking colored leather features:

1. It integrates rich and colorful colors of chemical fiber fabrics and biological properties of leather. Compared with the colorful chemical fiber fabrics, it is very easy to achieve a variety of color dyed chemical fiber fabrics, its tone is far more gentle than the color of chemical fiber fabrics, more full of three-dimensional sense and layering sense, and any chemical fiber fabrics can not only have the unique biological properties of leather it has;

2. Through special electrostatic treatment, the confusion caused by static charge accumulation is avoided, which broadens the application scope of leather, especially for the lining material of cars, which not only has luxurious and elegant tone and the essence of leather, but also solves the problem that the static charge accumulation that has puzzled people for a long time is easy to cause accidents;

3. The top surface graft dry milling resistant fastness is strong, more than 10000 times (GB/T13775), wet fastness is greater than 150 ℃;

4. The tensile fastness of finished leather is greater than 1 kg/m2 (see sg334-83);

5. In addition to the unique breathable, soft and plump characteristics of leather, it also has its unique washing resistance, easy cleaning, moisture insulation, noise insulation, flame retardant and other properties. The disadvantage of this new product is that it is made of leather after "planting" velvet on the leather, giving consumers the illusion that the product is nylon or artificial leather with the process in the 1960s and 1970s.

Anti Slip PVC Leathe

Anti Slip PVC Leathe SGS Eco Friendly Mic

SGS Eco Friendly Mic Special-Materials-Ne

Special-Materials-Ne Synthetic-PU-Leather

Synthetic-PU-Leather 7D Hand Craft Diamon

7D Hand Craft Diamon 0.45mm Best Price Sy

0.45mm Best Price Sy synthetic pu pvc vin

synthetic pu pvc vin PVC-Vinyl-Synthetic-

PVC-Vinyl-Synthetic- Flexible semi microf

Flexible semi microf Faux Paint To Paint

Faux Paint To Paint  Eco-friendly PVC Syn

Eco-friendly PVC Syn Bonded-embossed-leat

Bonded-embossed-leat Classic Leather Grai

Classic Leather Grai Animal Skin Emboss P

Animal Skin Emboss P ohms per square elec

ohms per square elec black conductive-pu-

black conductive-pu- black-color-screen-t

black-color-screen-t Synthetic-leather-fo

Synthetic-leather-fo Pattern-Faux-Synthet

Pattern-Faux-Synthet embossed-garment-pu-

embossed-garment-pu-